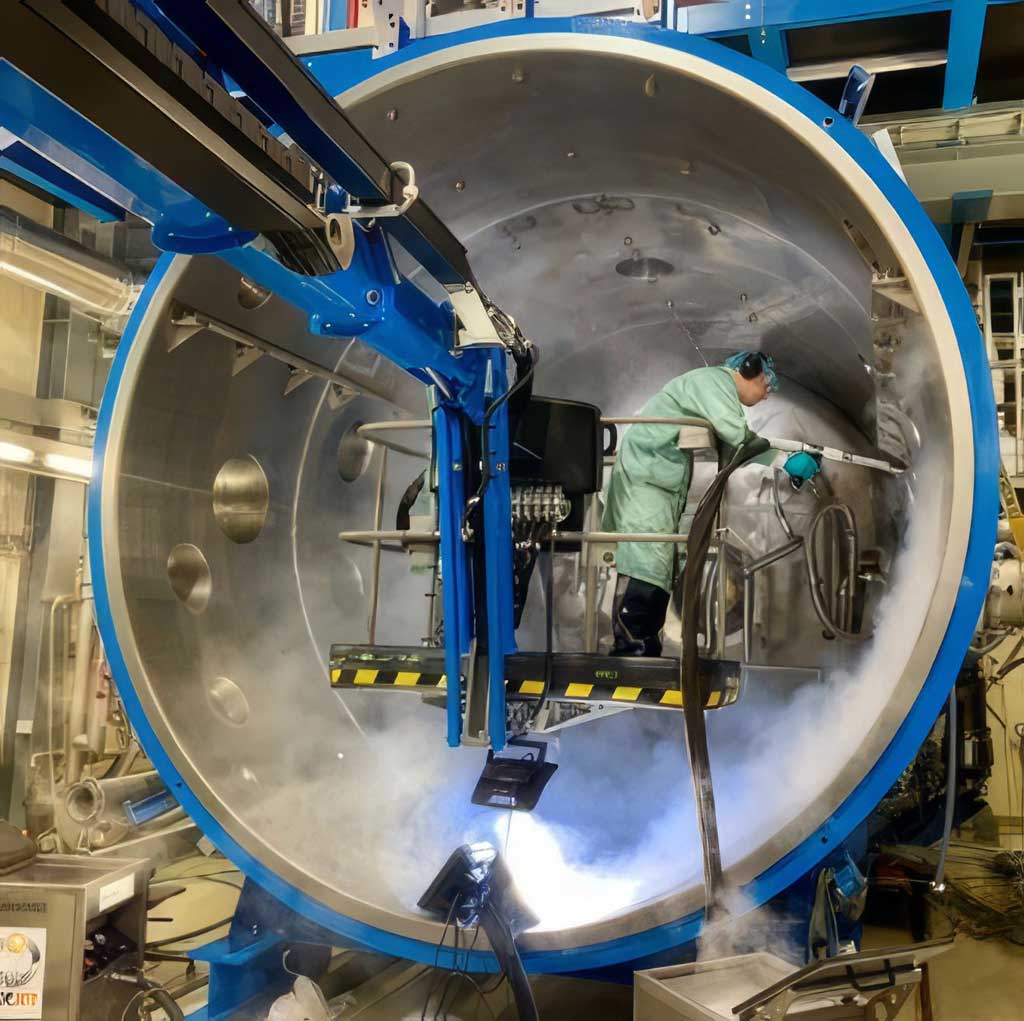

ICEBLASTING

Iceblasting or Dry ice-blasting is a type of cleaning based on carbon dioxide, where dry ice – the solid form of carbon dioxide – is propelled with compressed air flow onto a surface for cleaning.

The method is similar to other blasting cleaning methods such as sandblasting or soda blasting. The difference here is the medium, namely dry ice.

Iceblasting is considered the most environmentally friendly blasting cleaning method because dry ice, as it sublimates at room temperature, leaves no chemical residues.

The blasting is done by propelling dry ice in pellets at very high speeds. Upon impact, the soft pellets sublimate almost instantaneously, transferring minimal kinetic energy to the surface and thus causing minimal abrasion.

Sublimation absorbs a large amount of heat from the surface, generating intense friction from thermal shock. This process provides superior quality cleaning, as the upper layers of impurities and contaminants carry more heat than the substrates and, therefore, peel off much more easily.

Furthermore, the rapid transformation of the medium from solid to gas creates microscopic friction waves, thus providing more effective sanitation.

Iceblasting does NOT leave additional residues and/or DOES NOT create secondary contaminations, unlike blasts that use another medium (e.g., water blasting).

WHY SANDBLAST?